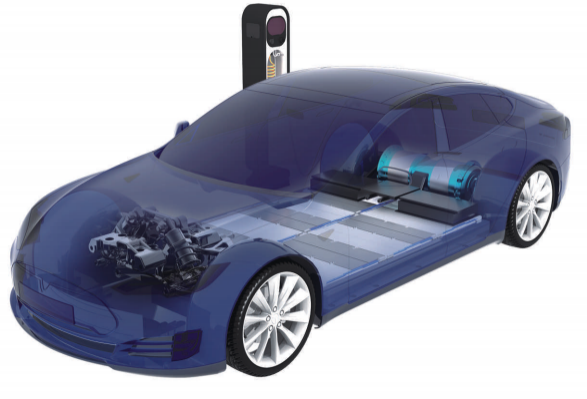

The global electric vehicle (EV) market is growing rapidly—and every gram matters.

Lighter cars mean longer driving range, higher efficiency, and lower production costs.

Automotive structural adhesives are becoming a critical solution, replacing traditional welds and rivets while improving design flexibility and performance.

Why Structural Adhesives Are Transforming EV Manufacturing

1. Lightweight Advantage

Metal fasteners add unnecessary mass.

High-strength structural adhesives distribute stress across the entire joint, reducing assembly weight by several kilograms—directly improving battery range.

2. Superior Energy Efficiency

Less weight means less energy use.

By bonding aluminum panels and composite battery housings, adhesives help extend mileage without expensive battery upgrades.

3. Enhanced Crash Safety

Adhesive bonds absorb and dissipate impact energy more evenly than spot welds, boosting crashworthiness and passenger protection.

4. Design Freedom for Complex Shapes

Modern EVs feature sleek curves and multi-material assemblies.

Structural adhesives allow engineers to join carbon fiber, plastics, and metals—no visible rivets or weld lines required.

5. Corrosion and Moisture Resistance

Adhesives create a continuous seal that protects against water, road salt, and chemicals, increasing durability and lowering maintenance costs.

Key EV Applications for Structural Adhesives

Battery Packs – Secure cells and modules, damp vibration, and improve thermal management.

Body Panels – Bond lightweight aluminum or composite panels instead of riveting for better aerodynamics.

Chassis Components – Strengthen joints and reduce heat distortion compared with welding.

Selecting the Right Electric Vehicle Adhesive

When choosing an EV structural adhesive, engineers should consider:

Operating Temperature – Battery systems experience wide thermal swings.

Chemical Resistance – Protection against electrolytes, coolants, and road chemicals.

Cure Speed – Fast-curing adhesives keep high-volume assembly lines moving.

Partnering with a trusted automotive adhesive supplier ensures optimal bonding strength and compliance with global automotive standards.

FAQs: Structural Adhesives in EVs

Q1: What are structural adhesives?

High-strength bonding agents designed to replace mechanical fasteners in load-bearing applications.

Q2: How do they benefit EVs?

They reduce weight, increase range, and provide superior crash protection.

Q3: Are they safe for high-voltage battery systems?

Yes—specialized formulas offer thermal stability and electrical insulation.

Q4: Can they bond aluminum to carbon fiber?

Absolutely. Advanced chemistries achieve primer-free adhesion across dissimilar substrates.

Q5: How long do adhesive bonds last?

With proper surface prep, bonds typically outlast the vehicle’s lifetime.

Work with a Proven EV Adhesive Partner

For manufacturers seeking lighter, longer-range electric vehicles, the right adhesive partner is key.

ODAKE delivers cutting-edge structural adhesive solutions for battery packs, body panels, and multi-material chassis design.

📍 Location: Dongguan City, Guangdong Province, China

🌐 Website: https://usodake.com

📧 Email: dghxxw888@163.com

📞 Phone: +86-769-81617120 | +86-13711910698

Get ahead in EV innovation with stronger, lighter, and greener structural bonding.