Introduction: A Turning Point for Industrial Threadlockers

Threadlockers have been a vital solution in industrial fastening for decades, preventing vibration-related loosening and protecting threads from corrosion. In 2025, the industry is experiencing a wave of innovations driven by sustainability goals, new materials science, and evolving manufacturing needs.

This article explores the latest developments and how they can benefit your operations.

1. Shift Toward Eco-Friendly Formulations

One of the biggest 2025 trends is the rise of low-VOC and bio-based threadlocker formulations.

Why it matters: Stricter environmental regulations and corporate ESG targets.

Innovation: Plant-derived monomers and water-dispersible threadlockers now offer the same bond strength as conventional formulas.

SEO keyword: eco-friendly industrial threadlocker

2. Faster Cure Times Without Compromising Strength

Downtime is costly. New chemistries in 2025 enable fixture strength in under 5 minutes at room temperature.

Industry driver: Automotive, electronics, and high-throughput manufacturing lines.

Example: Hybrid anaerobic-UV curing systems pre-set adhesive instantly before full anaerobic cure.

SEO keyword: fast curing threadlocker for production lines

3. High-Temperature & Chemical-Resistant Grades

Industrial operations are becoming harsher, especially in EV battery plants, aerospace, and chemical processing.

Performance: Up to 300°C heat resistance plus tolerance to aggressive solvents like acetone.

Benefit: Longer service life and fewer joint failures.

SEO keyword: high temperature chemical resistant threadlocker

4. Smart Indicators for Quality Control

New color-change curing indicators simplify QA inspections.

Function: Changes hue upon full cure for instant visual confirmation.

Applications: Aerospace safety systems, medical devices, high-reliability electronics.

SEO keyword: threadlocker with curing indicator

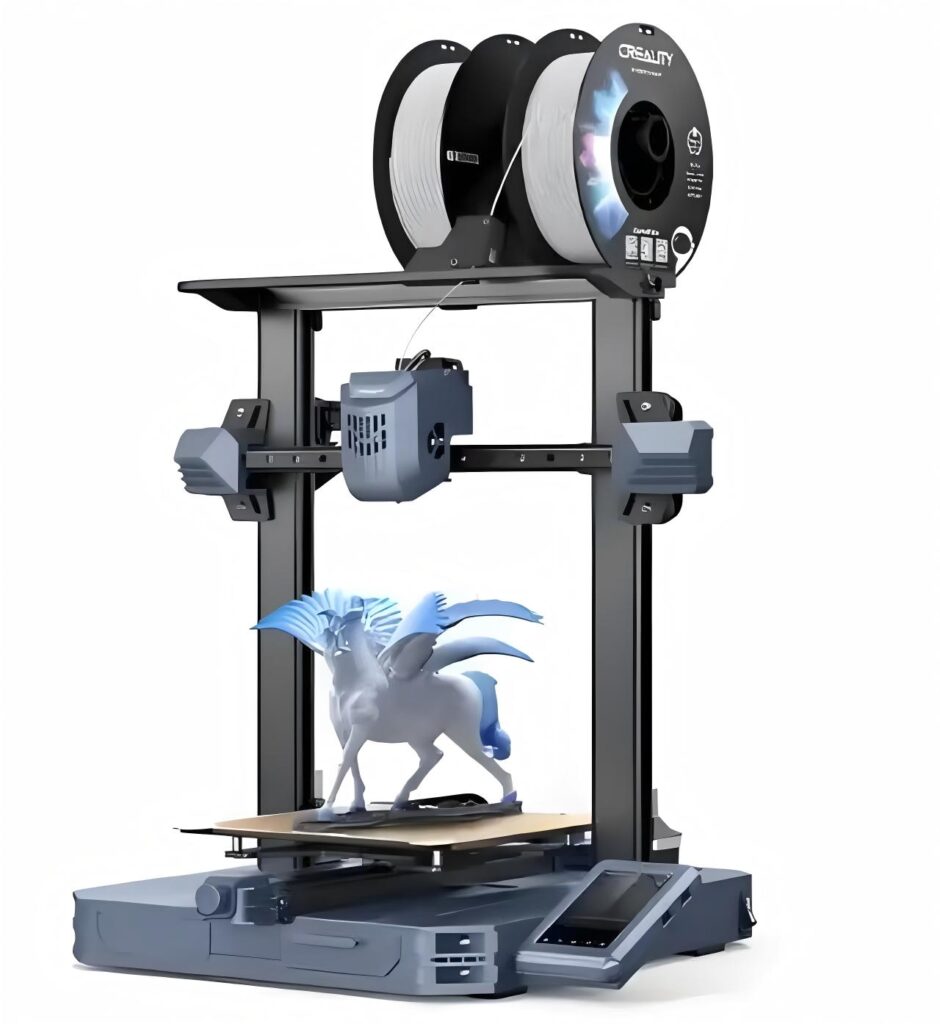

5. Expansion into 3D-Printed Components

As additive manufacturing grows, threadlockers are now engineered for polymers and composites.

Special feature: Flexible bonding and low-temperature cure to protect thermoplastics.

Impact: Enables reliable fastening in lightweight and custom-designed assemblies.

SEO keyword: threadlocker for 3D printed parts

How to Choose the Right Threadlocker in 2025

Environment: Temperature, vibration, and chemical exposure.

Bond strength: Temporary vs. permanent.

Cure speed: Match production needs.

Material compatibility: Metals, plastics, composites.

Regulatory compliance: VOC limits, RoHS, REACH.

Frequently Asked Questions (FAQ)

Q: What is the strongest industrial threadlocker in 2025?

A: High-strength, high-temperature threadlockers designed for permanent assemblies, withstanding up to 300°C and aggressive solvents, are the strongest options in 2025.

Q:Can threadlocker be eco-friendly?

A: Yes. Low-VOC and bio-based threadlockers introduced in 2025 meet environmental standards without sacrificing performance.

Q: How fast can modern threadlockers cure?

A: Some achieve fixture strength in under 5 minutes using hybrid anaerobic and UV-curing methods.

Q: Is there a threadlocker for plastic or 3D-printed parts?

A: Yes. New polymer-compatible formulas are designed for thermoplastics and additive manufacturing, offering flexible and low-temperature curing.

Q: How do I remove cured high-strength threadlocker?

A: Typically requires localized heat above 250°C plus mechanical tools; solvents are available for sensitive assemblies.

📞 Want Expert Guidance on Choosing the Right Threadlocker?

At Odake (Hexu Xinwang Adhesive Co., Ltd.), we manufacture a full range of certified industrial threadlockers for electronics, automotive, aerospace, and sustainable packaging applications.

Our team provides:

Technical consultation for product selection and application

OEM/ODM support to match your production needs

Global delivery for fast, reliable supply

📍 Dongguan, China

🌐 https://usodake.com

📧 Email: dghxxw888@163.com

📞 Phone: +86-769-81617120 | +86-13711910698