Odake Adhesive Expert Insight: Why Food-Contact Appliances Need True “Food-Contact Adhesives”

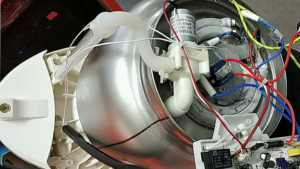

In modern household appliances such as smart tea makers, health kettles, water dispensers and insulated cups, components that come into contact with drinking water, steam and hot liquids must meet strict requirements: food safety, high-temperature resistance, waterproof sealing, multi-material compatibility and clear appearance.

As the Odake Adhesive Experts, we developed CT775A Food-Contact Adhesive — a clear silicone glue / silicone sealant engineered specifically for food-contact applications. It combines food-grade safety, strong bonding performance and long-term durability, and has fully passed customer validation tests.

1. Food-Contact Safety: Truly Meets FDA Requirements

From the beginning, Odake CT775A was designed as an adhesive suitable for drinking-water pathways.

Key advantages include:

Food-grade silicone formulation

Alcohol-release curing system: non-corrosive and non-toxic

Formulation aligned with FDA food-contact safety requirements

Low odor, solvent-free, compliant with ROHS/REACH/VOC regulations

Ideal for:

glass parts in tea makers, silicone tubing in water dispensers, glass pot sealing, insulated cup lid gaskets, ceramic components in tea ware and more.

2. Multi-Material Compatibility: True Engineering-Level Bonding

Based on customer test feedback, CT775A successfully achieved strong bonding in the following combinations:

Glass ↔ PC

Glass ↔ Stainless steel

Silicone tubing ↔ Silicone tubing

Sealing ring ↔ Stainless steel

Ceramic ↔ Ceramic

The high-performance silicone system of CT775A allows it to bond both rigid smooth materials (glass, stainless steel) and flexible substrates (silicone), making it ideal for complex food-contact appliance structures.

3. Temperature Resistance: Continuous 100°C, Peak up to 235°C

According to TDS data, CT775A features a wide operating temperature range of -60°C to 235°C.

Engineers will appreciate its stability under conditions such as:

Hot-water sections inside tea makers

Sealing zones at the bottom of health kettles

Silicone tubing joints in drinking-water systems

Insulated cup lid seals

CT775A maintains flexibility without cracking or delamination, and resists yellowing even under long-term heat.

4. Waterproof Sealing Performance: Designed for IPX Protection

As a silicone sealant, CT775A cures into a flexible elastomer that provides:

Long-term waterproof and immersion resistance

Reliable adhesion under hot–cold cycling

Clear, non-yellowing appearance

Smooth dispensing with minimal bubbles and low shrinkage

These characteristics are essential for appliances that require IPX waterproof ratings or long-term liquid exposure.

5. Real Engineering Parameters (from TDS) Demonstrate Reliability

Viscosity: 15,000–20,000 CPS (high viscosity, non-sag)

Shore A hardness: 18–28

Tensile strength: ≥1 MPa

Elongation at break: ≥200% (absorbs vibration and impact)

Tack-free time: 10–15 minutes

Full cure: 24 hours

Excellent insulation: ≥1×10¹⁴ Ω·cm (safe for components near electrical circuits)

These specifications allow CT775A to achieve a balanced performance between bonding strength, flexibility and long-term sealing stability.

The Most Trusted Adhesive for Food-Contact Appliance Manufacturing

If you are looking for:

A true food-contact adhesive

An adhesive that meets FDA safety standards for drinking-water paths

A clear, high-temperature silicone glue that resists steam, heat and yellowing

A durable silicone sealant with both structural bonding and waterproof sealing performance

Then Odake CT775A is the professional solution engineered specifically for food-contact home appliances.