In medical device manufacturing, catheters, needle hubs and sensor components demand adhesives with high bonding strength, proven biocompatibility and excellent environmental resistance. Leveraging years of formulation expertise, Odake offers a series of ISO 10993-5 certified UV-curing adhesives engineered specifically for medical applications, including:

-

CT8886 Medical UV Adhesive

-

CT8886A Low-Viscosity UV Adhesive

-

CT8888 High-Temperature UV Adhesive (up to 180°C)

-

CT8888C Ultra-Clear, High-Strength UV Adhesive

All adhesives are single-component, solvent-free and fast-curing, making them ideal for automated production lines and high-volume manufacturing.

1. Engineered for a Wide Range of Medical Bonding Applications

Odake medical UV adhesives are used extensively in:

-

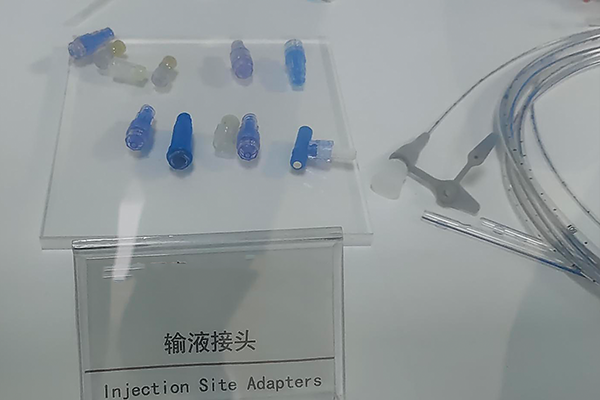

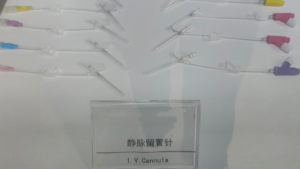

IV cannulas

-

Infusion needle hubs

-

Catheters and tubing

-

Anesthesia masks

-

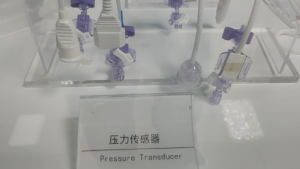

Pressure and flow sensors

-

Disposable transparent medical components

They deliver excellent adhesion across a wide selection of materials commonly used in medical device assembly:

Supported Materials

-

TPU → TPU

-

PVC → PVC

-

PVC → PC

-

PC → ABS

-

PC → PC

-

Mixed material assemblies (TPU/PVC/PC/ABS)

-

Transparent medical plastics such as PC, PMMA and Nylon

The urethane acrylate chemistry offers both flexibility and impact resistance, ensuring durable bonding even on thin-wall components and soft plastics.

2. Proven Performance in Real-World Medical Testing

Odake adhesives have demonstrated exceptional results in customer validation tests:

✔ Tensile Strength (10–25 N)

Reliable for catheter joints, needle assemblies and soft-to-hard plastic bonds.

✔ Fluorescent Dye Leakage Test

No leakage detected — fully compliant with sealing standards.

✔ Salt-Spray Resistance (24–48 hours)

No rust, cracking or adhesive failure under harsh environments.

✔ Chemical & Chlorine Resistance (24 hours)

No corrosion, discoloration or degradation of adhesive strength.

These results confirm that Odake adhesives not only excel in transparent part bonding but also deliver leak-proof sealing, structural fixation and long-term corrosion resistance.

3. Precision Manufacturing with Fast, Clean UV Curing

Under 365 nm UV light:

-

5–15 seconds to surface-cure

-

15–60 seconds for deep cure (1–3 mm)

-

High clarity with no yellowing

-

Smooth, clean bond lines

-

No mixing required — simple, single-component workflow

-

Perfect for automated dispensing systems

Ideal for high-throughput medical production such as catheter hubs and infusion sets.

4. Why Leading Medical Manufacturers Choose Odake

-

ISO 10993-5 certified for biocompatibility

-

Stable medical-grade formulation with no leaching

-

Superior performance on TPU, PVC and other soft plastics

-

Fast curing for maximized production efficiency

-

Water-clear, non-yellowing appearance

-

Supported by multiple successful customer case studies

Odake medical UV adhesives offer a reliable combination of safety, strength, process efficiency and consistent production quality.

If you need a high-performance medical adhesive for device assembly—balancing strength, sealing performance and biocompatibility—the Odake CT-series is a trusted choice.

For technical recommendations, samples or project-specific guidance, our team is ready to support you one-on-one.