Anaerobic Adhesive threadlocker | Locking, sealing, filling gaps, optional strength

Suitable for automotive industry, electronics, aerospace, energy equipment, daily maintenance, etc.

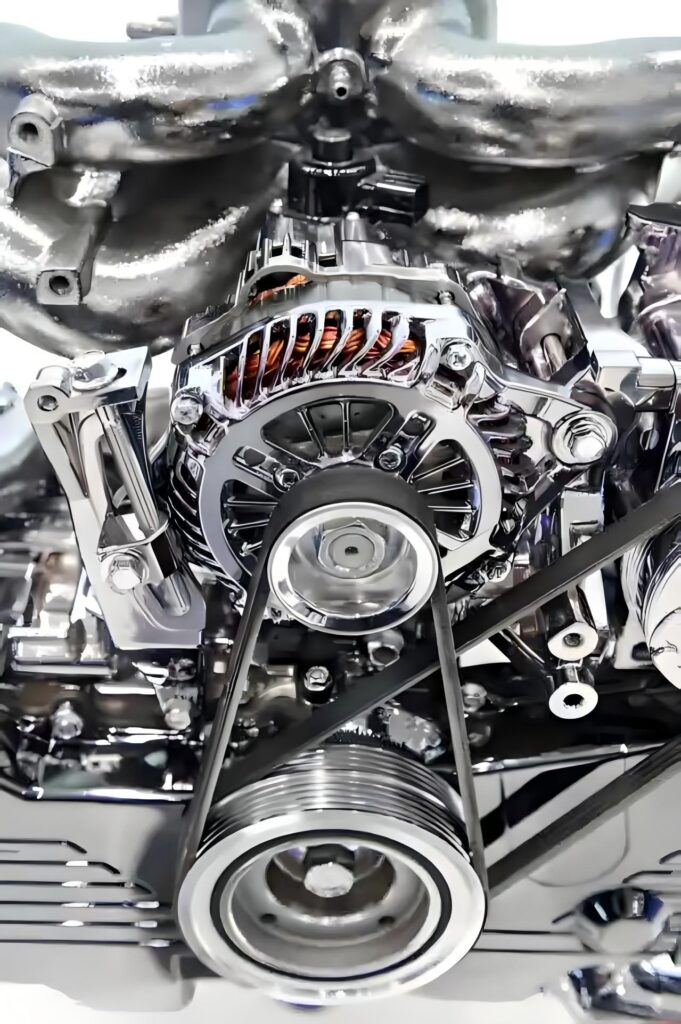

ODAKE anaerobic adhesives deliver exceptional bonding strength, sealing performance, and chemical resistance for metal-to-metal applications. Ideal for threaded fasteners, shafts, bearings, and piping systems, our adhesives are engineered for automotive, aerospace, manufacturing, electronics, HVAC, and food-grade applications.

Certified to ROHS, REACH, VOC, and NSF standards, ODAKE products meet the most demanding global requirements. We provide OEM/ODM adhesive manufacturing, support bulk industrial orders, and ensure fast worldwide delivery.

Contact Hexu Xinwang today for expert consultation, free samples, or bulk order quotes.

Locks and seals threaded fasteners to prevent loosening from vibration, thermal cycling, or mechanical stress.

Suitable for bolts, screws, studs in automotive, aerospace, and industrial machinery.

Resists oil, chemicals, and high heat.

Safe for potable water, food processing equipment, and beverage machinery.

Non-toxic, high chemical resistance, meets NSF safety standards.

Secures cylindrical assemblies like bearings, bushings, and shafts.

Fills microscopic gaps for uniform stress distribution.

Prevents corrosion, fretting, and loosening under heavy loads.

✅ Gap-Filling & Sealing – Forms a secure, leak-proof seal to prevent corrosion and contamination.

✅ High Shear & Tensile Strength – Reliable performance under vibration, load, and extreme temperature.

✅ Chemical, Oil & Heat Resistance – Withstands -50°C to 180°C (up to 230°C for high-heat grades).

✅ NSF-Certified Food Contact Grades – Approved for safe use in food and water systems.

✅ Multiple Viscosity Options – From low-viscosity for small fasteners to high-viscosity for large gaps.

Applications include:

Thread locking for bolts and screws to prevent loosening from vibration

Sealing fluid systems such as fuel, coolant, and transmission lines

Retaining bearings, shafts, and pulleys

Preventing corrosion and galling in engine components

Benefit: Enhances reliability, reduces the need for mechanical fasteners, and lowers long-term maintenance costs.

Applications include:

Fixing cylindrical parts like gears, keys, and bushings

Preventing fretting corrosion in dynamic assemblies

Pipe thread sealing for hydraulic and pneumatic systems

Benefit: Increases operational safety and machine uptime in high-load environments.

Applications include:

Fastener sealing in consumer appliances

Locking screws in power tools and handheld equipment

Sealing fluid manifolds and mechanical enclosures

Benefit: Enhances product quality and assembly efficiency while maintaining consistent curing performance.

Applications include:

Sealing threaded pipe fittings to prevent leaks

Locking and sealing valves, gauges, and pressure regulators

Assembly of HVAC components requiring vibration resistance

Benefit: Replaces PTFE tapes or mechanical seals for long-lasting, leak-proof joints.

Applications include:

Miniature fastener bonding in control panels

Sealing connectors in electronic enclosures

Retaining shafts and bearings in small motors

Benefit: Ensures electrical integrity and protects sensitive components from environmental exposure.

Applications include:

Sealing pipe systems in water purification units

Fastener locking in beverage dispensers

Use in dairy processing and commercial kitchen equipment

Benefit: Complies with stringent health and safety regulations, ensuring non-toxicity and leak prevention.

Applications include:

Bonding metal inserts in surgical instruments

Assembling diagnostic equipment with minimal residue

Thread locking in precision medical assemblies

Benefit: Offers biocompatibility, sterility support, and precision assembly under regulated conditions.

Applications include:

Sealing hydraulic fittings in wind turbines

Locking fasteners in power distribution boxes

Retaining parts in electrical motor assemblies

Benefit: Ensures mechanical reliability in critical infrastructure operations.

Applications include:

Sealing pump and compressor housings

Locking and sealing pipework exposed to solvents

Retaining parts in corrosive gas systems

Benefit: Increases safety and longevity of chemical systems with minimal leakage risk.

A: An anaerobic adhesive is a type of adhesive that cures in the absence of oxygen and in the presence of metal ions. It is commonly used as a threadlocker, retaining compound, or sealant for metal components in industrial, automotive, and mechanical applications.

A: ODAKE Threadlockers & Sealants provide high bonding strength, vibration resistance, leak prevention, and chemical resistance. They also meet ROHS, REACH, and NSF certifications, making them safe for a wide range of applications, including food and potable water systems.

A: Yes. ODAKE threadlocker adhesives are suitable for stainless steel, carbon steel, and coated metals. For low-reactivity metals like stainless steel, using a primer can speed up curing time.

A: Low strength – Removable with hand tools, ideal for small fasteners.

Medium strength – Strong hold but removable with standard tools, suitable for most automotive and industrial uses.

High strength – Permanent bonding for critical components, requires heat or special tools for removal.

A: Yes. Most ODAKE anaerobic adhesives resist temperatures from -50°C to 180°C, while specialized high-temperature grades can withstand up to 230°C.

📧 邮箱:hexuxinwang@odakeglue.com

📞 电话:+86-769-81617120 | +86-13711910698

📍 地址:广东省东莞市虎门镇龙岩东路十二巷23号

*We respect your confidentiality and all information is protected.

ODAKE is a trademark of Hexun Xinwang Adhesive.

We will arrange for a specialist to contact you immediately.