In the demanding world of automotive repair, threadlocker adhesives are an unsung hero. These specialized anaerobic adhesives secure threaded fasteners, preventing loosening caused by vibration, thermal cycling, or shock. Whether you’re fixing a family sedan or servicing a performance car, threadlockers ensure reliability, safety, and long-term performance.

In this article, we’ll explore 10 real-world applications of threadlocker in automotive repair—covering everything from engine assembly to suspension work.

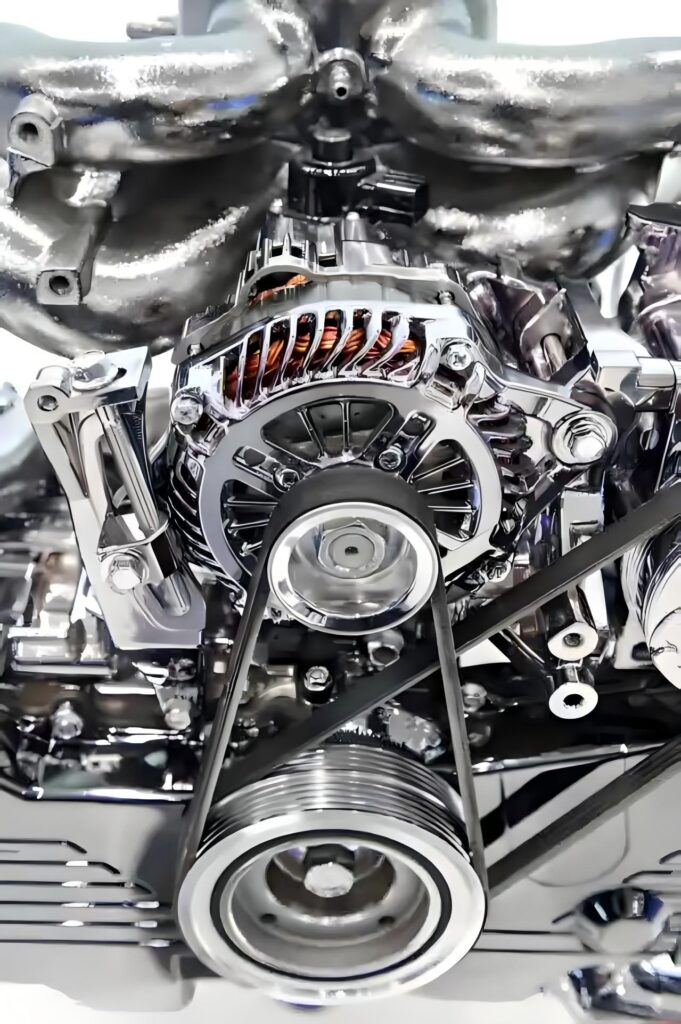

1. Engine Assembly

Threadlocker is used to secure bolts in cylinder heads, camshaft caps, and timing components. The constant heat and vibration inside an engine can cause untreated bolts to loosen, but a high-temperature threadlocker ensures a secure, leak-free seal.

2. Brake Calipers and Rotors

Brake systems experience extreme vibration and heat. Applying threadlocker to caliper bracket bolts prevents loosening and reduces the risk of brake failure.

3. Transmission Mounting Bolts

Automatic and manual transmissions both generate vibration that can loosen bolts over time. Threadlocker ensures the mounting hardware stays secure for smooth, reliable gear shifts.

4. Suspension Components

Control arms, sway bars, and shock absorber mounts are under constant stress. Threadlocker locks these bolts in place, preventing dangerous loosening during high-speed driving or off-road use.

5. Steering Systems

From rack-and-pinion assemblies to tie-rod ends, threadlocker ensures the safety of critical steering connections, reducing the risk of loss of control.

6. Differential and Driveshaft Fasteners

Drivetrain components transfer massive torque. Threadlocker on differential cover bolts and driveshaft flange bolts helps prevent leaks and maintains proper torque settings.

7. Exhaust System Bolts

Thermal expansion and contraction can loosen exhaust fasteners. High-temperature threadlocker withstands extreme heat, keeping manifolds, catalytic converters, and mufflers tightly secured.

8. Fuel System Connections

Threadlocker can be used on certain threaded fuel system parts to prevent vibration-related leaks while resisting fuel exposure.

9. Body and Frame Mounting Hardware

Threadlocker is used on door hinges, hood latch bolts, and bumper mounts to prevent noise, vibration, and misalignment.

10. Wheel Hub Assemblies

Threadlocker secures axle nuts, wheel hub bolts, and related hardware to ensure proper wheel alignment and prevent premature wear.

Choosing the Right Threadlocker for Automotive Repair

When working on vehicles, selecting the correct threadlocker strength is critical:

Low Strength – For fasteners that require easy removal, such as interior trim screws.

Medium Strength – Ideal for most automotive bolts, offering strong hold but removable with hand tools.

High Strength – For permanent bonds on safety-critical components.

High-performance automotive-grade threadlockers also offer:

Oil tolerance for use on pre-assembled parts.

High-temperature resistance for engine and exhaust areas.

Compatibility with different metals and coatings.

Final Thoughts

Threadlocker is a small investment that delivers major benefits—better reliability, fewer repeat repairs, and improved safety. Whether you’re a professional mechanic or a DIY enthusiast, using the right threadlocker in the right place ensures your repair lasts.

About Odake (Hexu Xinwang Adhesive Co., Ltd.)

At Odake, we manufacture a complete range of industrial and automotive-grade threadlockers for electronics, automotive, aerospace, and sustainable packaging applications.

Our Advantages:

Technical Consultation – Expert guidance for product selection and application.

OEM/ODM Support – Custom formulations to meet specific production needs.

Global Delivery – Reliable supply to customers worldwide.

Certified Quality – REACH and RoHS compliant, tested for performance and safety.

📍 Dongguan, China

🌐 usodake.com

📧 Email: dghxxw888@163.com

📞 Phone: +86-769-81617120 | +86-13711910698