ODAKE 2-part Epoxy Structural Adhesive Series is a high-performance, two-component epoxy adhesive system composed of Part A (epoxy resin) and Part B (specialized curing agent). Upon thorough mixing, a strong catalytic reaction occurs, resulting in a durable bond with excellent mechanical strength and reliable encapsulation properties.

This epoxy adhesive series offers superior adhesion to a wide range of substrates, including metals, carbon fiber, ceramics, glass, stone, jewelry, wood, as well as select plastics and rubbers, making it an ideal solution for industrial manufacturing, electronics assembly, and precision bonding applications.

Fully compliant with ASTM standards, and meeting stringent EU REACH and RoHS regulations, the ODAKE 2-part Epoxy Structural Adhesive Series is safe, non-toxic, and environmentally friendly, ensuring reliable performance without compromising on health or environmental safety.

Safe and non-toxic

Exceptional Bond Strength

Durable & Insulating

Wide Service-Temperature Range

50ML/stick

400ML/stick

Glue A and glue B should be stored separately in a dry, low-temperature, light-proof environment. The shelf life is 6 months.

ODAKE 2-part Epoxy Structural Adhesive Series is a high-performance, 2-part epoxy adhesive engineered for structural bonding and electronic encapsulation. It is highly versatile, offering strong adhesion to metal, plastic, ceramic, wood, and rubber, making it ideal for a wide range of industrial and consumer product assembly needs.

Typical Applications Include:

Lighting equipment and LED modules

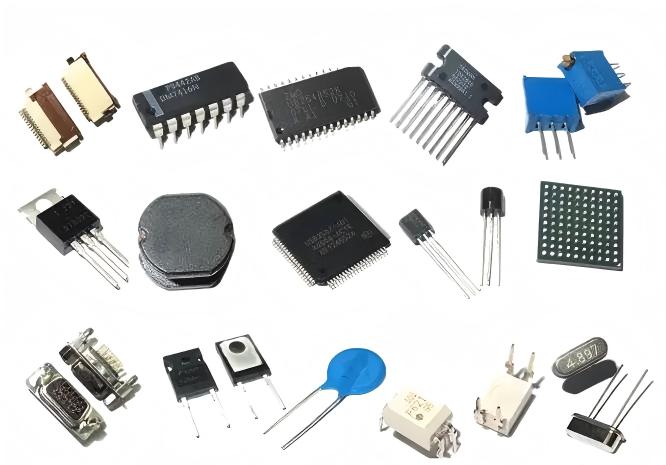

Electronic components

Home appliances and kitchen devices

Mechanical and motor assemblies

Crafts and decorative items

Audio-visual equipment

Personal care devices

Automotive parts

| Product Model | CT6811 | CT6825 | CT6826 | |||

| A Glue | B Glue | A Glue | B Glue | A Glue | B Glue | |

| Color | Black | Light yellow liquid | Milky | Amber | Black | Orange |

| Characteristic | Bonding, potting,Odorless, waterproof, high and low temperature resistant | Bonding,Strong adhesion, waterproof, high and low temperature resistance | Bonding, caulking, repairing,No shrinkage after curing, can be polished and drilled, resistant to high and low temperatures | |||

| Viscosity@25℃ CP | 12000 | 9000 | Semi-liquid | |||

| Initial setting time after AB glue mixing (hours) | 1 | 2-4 | 1-2 | |||

| Full solidification time (hours) | 24 | |||||

| Temperature range (℃) | -40~140 | -50~150 | -50~180 | |||

| Hardness (Shore A) | 80~86 | 80~82 | 85~87 | |||

| Volume mixing ratio | 1:1 | |||||

| Weight Mixing Ratio | 1.17 :1.06 | 1:0.8 | ||||

| Shear strength (MPa) ≥ | 8 | 25 | 18 | |||

| Other | Thermal conductivity (W/M.K):0.2 | Light transmittance:0.9 | ||||

Disclaimer

The data provided in this document are representative values derived from actual measurements and routine testing. Hexu Xinwang assumes no responsibility for data obtained through unauthorized personnel or testing methods not approved by the company. Due to variations in application conditions, the above information should be adapted to the user’s specific circumstances. Hexu Xinwang accepts no liability for individual cases, including, but not limited to, any loss of profits.

📧 邮箱:hexuxinwang@odakeglue.com

📞 电话:+86-769-81617120 | +86-13711910698

📍 地址:广东省东莞市虎门镇龙岩东路十二巷23号

*We respect your confidentiality and all information is protected.

ODAKE is a trademark of Hexun Xinwang Adhesive.

We will arrange for a specialist to contact you immediately.