ODAKE CT7612 is a low-viscosity, two-component addition-cure silicone encapsulant designed for effective thermal management and protective potting of sensitive electronic components. It cures efficiently at room temperature or faster with heat, without releasing any by-products during the curing process.

This versatile encapsulant is compatible with a variety of substrates, including polycarbonate (PC), polypropylene (PP), ABS, PVC, and a wide range of metal materials.

Fully compliant with EU RoHS directives, ODAKE CT7612 is non-toxic, environmentally safe, and engineered to withstand high humidity, elevated temperatures, and vibration-prone environments. Once cured, it delivers excellent thermal conductivity, moisture resistance, and long-term mechanical stability, making it ideal for durable electronic component protection.

Excellent adhesion and encapsulation performance

Durable seal, moisture and shock resistance

Withstands extreme temperatures from -40°C to 200°C

Dual curing modes: room temperature or accelerated heat curing

Low viscosity for easy potting and gap filling

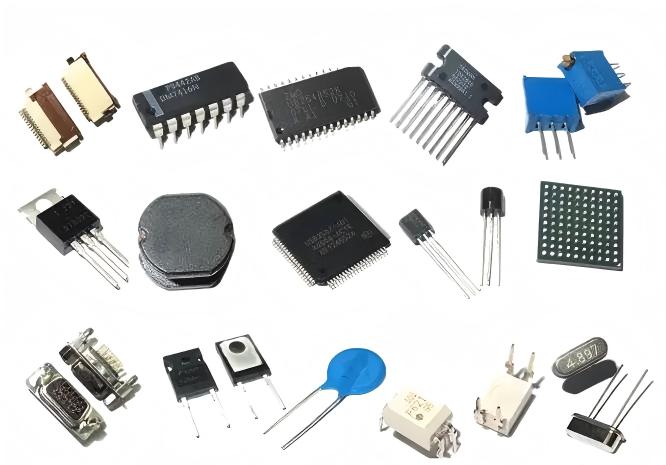

ODAKE CT7612 Thermal Conductive Silicone Potting Compound is ideal for the encapsulation, thermal management, and environmental protection of electronic and electrical components. Typical applications include:

Power supplies — heat dissipation and dielectric protection

Electric motors and coils — insulation and vibration damping

Printed circuit boards (PCBs) — moisture-proof and thermal shielding

Electronic components and modules — protective potting and sealing

Devices operating in high-humidity or high-temperature environments — long-term reliability assurance

| Product Model | CT7612 | |||

| Component A | Component B | Inspection Standards | ||

Before curing | Appearance | Gray fluid | Black fluid | Q/ZS 1-2016 |

| Viscosity (cps) | 2000±3000 | 2000-3000 | GB/T 10247 | |

| Mix ratio A:B (weight ratio) | 1 ∶ 1 | Q/ZS 1-2016 | ||

| Viscosity after mixing (cps) | 2000~3000 | GB/T 10247 | ||

| Room temperature application time (min) | 40-70 | Q/ZS 1-2016 | ||

| Typical curing time | / | 24h@25℃ or 2h@80℃ | ||

After curing | Hardness (shore D) | 83±2 | GB/T 531-200 | |

| Thermal conductivity (W/m·k) | 1.0-1.2 | GB/T 10294-2008 | ||

Disclaimer

The data provided in this document are representative values derived from actual measurements and routine testing. Hexu Xinwang assumes no responsibility for data obtained through unauthorized personnel or testing methods not approved by the company. Due to variations in application conditions, the above information should be adapted to the user’s specific circumstances. Hexu Xinwang accepts no liability for individual cases, including, but not limited to, any loss of profits.

Mixing Procedure

Measure the required amount of Part A and Part B according to the recommended mixing ratio. Pour each component into a clean, dry container, and stir thoroughly in one direction to ensure a uniform mixture. Vacuum degas the mixed material to remove air bubbles before applying.

⚠️ Avoid reintroducing any mixed or contaminated material back into the original containers of Part A or B. Seal and store components separately after use.

Mixing Tips

Stir along one consistent direction to minimize air entrapment.

Scrape and mix material along the sides and bottom of the container to prevent incomplete curing due to uneven mixing.

The larger the mixed batch, the shorter the pot life will be.

Higher ambient temperatures will accelerate the curing process, so adjust working time accordingly.

Curing Conditions

The material can cure at room temperature or faster under elevated temperatures. Choose the curing method based on production needs and substrate characteristics.

📧 邮箱:hexuxinwang@odakeglue.com

📞 电话:+86-769-81617120 | +86-13711910698

📍 地址:广东省东莞市虎门镇龙岩东路十二巷23号

*We respect your confidentiality and all information is protected.

ODAKE is a trademark of Hexun Xinwang Adhesive.

We will arrange for a specialist to contact you immediately.