ODAKE One Part Epoxy Structural Adhesives Series is a high-performance, thermosetting adhesive designed for robust structural bonding across a wide range of substrates, including metals, plastics, and ceramics. This one-component epoxy offers exceptional mechanical strength, outstanding impact resistance, and superior crack resistance, ensuring durable and reliable bonds in demanding industrial environments.

Formulated to meet strict international quality and safety standards, the ODAKE epoxy adhesives are non-toxic, environmentally friendly, and comply with global regulations such as RoHS and REACH. Their excellent thermal and chemical resistance makes them ideal for use in electronics assembly, industrial manufacturing, automotive components, and heavy machinery applications.

The ease of use of a single-component system combined with strong adhesion and excellent gap-filling properties allows for efficient structural bonding and encapsulation, reducing assembly time and improving overall product reliability.

Non-toxic and environmentally responsible

Single-Component, Heat-Curabl

High Bond Strength

High temperature resistance, no corrosion

Excellent Toughness & Insulation

30ml/tube

50ml/tube

Store below -20 degrees, long-term use(CT361,CT371,CT373);

Store below 5 degrees, long-term use(CT363).

Store at 2-8 degrees for 180 days(CT375).

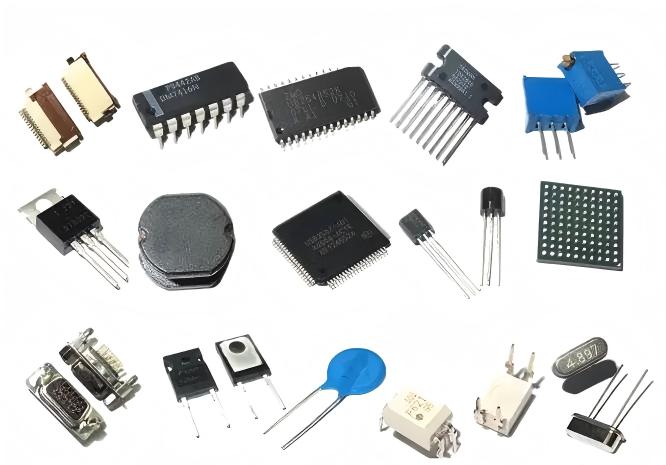

ODAKE one-component epoxy structural adhesive series is designed for heat curing and is ideal for applications that require precision, durability and thermal stability, especially for bonding delicate and heat-sensitive electronic components.

Typical Applications

Electric Motors

Electronic Components

Semiconductors & Chips

Automotive Parts

Mechanical Assemblies

| Product model | CT361 | CT371 | CT373 | CT375 | CT363 | |

| Sample curing status | Curing at 80℃ for 6 minutes | Curing at 150℃ for 30 minutes | Curing at 80℃ for 6 minutes | Curing at 80℃ for 30 minutes | ||

| Physical properties | Typical value | Test standard | ||||

| Color | Black liquid | / | ||||

| Hardness (Shore D) | 72 | 85 | 76 | 72 | GB/T 2411-1980 | |

| Shear strength (MPa) | 16 | 26 | 26 | 27 | 16 | GB/T 7124-2008 |

| Elongation at break (%) | 2 | GB 1040-1992 | ||||

| Glass transition temperature (℃) | 112 | 116 | 148 | 112 | GB 19466.2-2004 | |

| Coefficient of thermal expansion | < Tg 50 | < Tg 50(10- 6/℃(Tg 以下) | < Tg 24 | ASTM E831-86 | ||

| > Tg 160 | > Tg 185 | |||||

| Water absorption (%) | 0.12 (24h@25℃) | 0.16(24h@25℃) | 0.56( wt% ,ASTM570) | GB/T 1034-1998 | ||

| Dielectric constant/dielectric loss | 1KHz: 3.3/0.02 | 1KHz: 5.45/0.038 | GB/T 1693-2007 | |||

| 100KHz: 3.0/0.03 | 1MHz: 4.41/0.056 | |||||

| Dielectric strength (KV/mm) | 26.5 | 31.5 | 26.5 | GB1408.1-1999 | ||

| Ty iu Surface resistance (Ω) | 2.1×1015 | 1.5×1015 | 2.1×1015 | GB/T 1410-2006 | ||

| Volume resistance (Ω.cm) | 2.1×1015 | 2.3×1017 | 2.1×1015 | GB/T 1410-2006 | ||

Disclaimer

The data provided in this document are representative values derived from actual measurements and routine testing. Hexu Xinwang assumes no responsibility for data obtained through unauthorized personnel or testing methods not approved by the company. Due to variations in application conditions, the above information should be adapted to the user’s specific circumstances. Hexu Xinwang accepts no liability for individual cases, including, but not limited to, any loss of profits.

CT361,CT373 curing time:80°C: 6-8 min | 90°C: 4-6 min

CT363 curing time:80°C: 30 min | 100°C: 7-10 min

CT371 curing time:130°C: 45 min | 140°C: 30 min | 150°C: 25 min

CT375 curing time:120°C: 60 min | 150°C: 30 min

After heating, the glue will react and cure faster. The curing speed and strength depend on the heating temperature and time. The higher the temperature, the shorter the curing time. The heating temperature and time should be appropriately adjusted according to the heating efficiency of the heating equipment and the bonded material to obtain the best process parameters.

*We respect your confidentiality and all information is protected.

ODAKE is a trademark of Hexun Xinwang Adhesive.

We will arrange for a specialist to contact you immediately.