UV curing/UV+moisture dual curing | coating, bonding, sealing, repairing, etc.

Safe and environmentally friendly, suitable for electronics, medical equipment, optical instruments, industrial manufacturing, etc.

ODAKE UV-curable adhesives deliver fast curing speed, exceptional clarity, and high bonding strength for electronics, medical devices, optics, automotive, and industrial manufacturing.

Certified to ROHS, REACH, VOC, and FDA standards, our adhesives are trusted worldwide for precision assembly, strong durability, and aesthetic finish.

Contact us now for a customized quote, product samples, or more information about our OEM/ODM services.

Specially formulated for medical device assembly, providing biocompatibility, low toxicity, and high clarity.

Applications: Catheters, diagnostic tools, wearable devices.

✔ ISO10993-5 & FDA-grade options

✔ Sterilization-resistant bonding

Ideal for PCB solder joint reinforcement and wire terminal sealing. Creates a durable insulating layer against heat, vibration, and moisture.

✔ Rapid UV curing for mass production

✔ RoHS & REACH compliant

Engineered for challenging substrates like ABS, PVC, stainless steel, and aluminum.

✔ High transparency for visible parts

✔ Multiple viscosity grades available

Ultra-Fast UV Curing – Bonds in seconds to speed up production lines.

Dual-Cure Technology (UV + Moisture) – Perfect for shaded areas where UV light cannot fully reach.

Crystal-Clear Finish – Ideal for glass, acrylic, optics, and decorative elements.

Low Odor & VOC-Compliant – Safe for operators and environmentally friendly.

Excellent Adhesion & Durability – Works with plastic, metal, glass, ceramics, and composites.

Adjustable Viscosity – From low-flow for precision to high-viscosity pastes for structural bonding.

Custom Formulations – Tailored curing speed, flexibility, tensile strength, or adhesive color.

ODAKE high-performance UV curing adhesives are trusted across industries where speed, precision, and durability are critical.

Applications: Bonding PCBs, speaker modules, smartphone parts, sensors, connectors.

Benefits: Ultra-fast curing for high-volume production, non-corrosive, excellent electrical insulation.

Applications: Lenses, prisms, optical filters, fiber optics, camera modules.

Benefits: High transparency, low shrinkage, precise alignment for optical performance.

Applications: Catheters, diagnostic equipment, syringes, dental tools, wearable health devices.

Benefits: Biocompatible (ISO10993-5), FDA-compliant, sterilization-resistant.

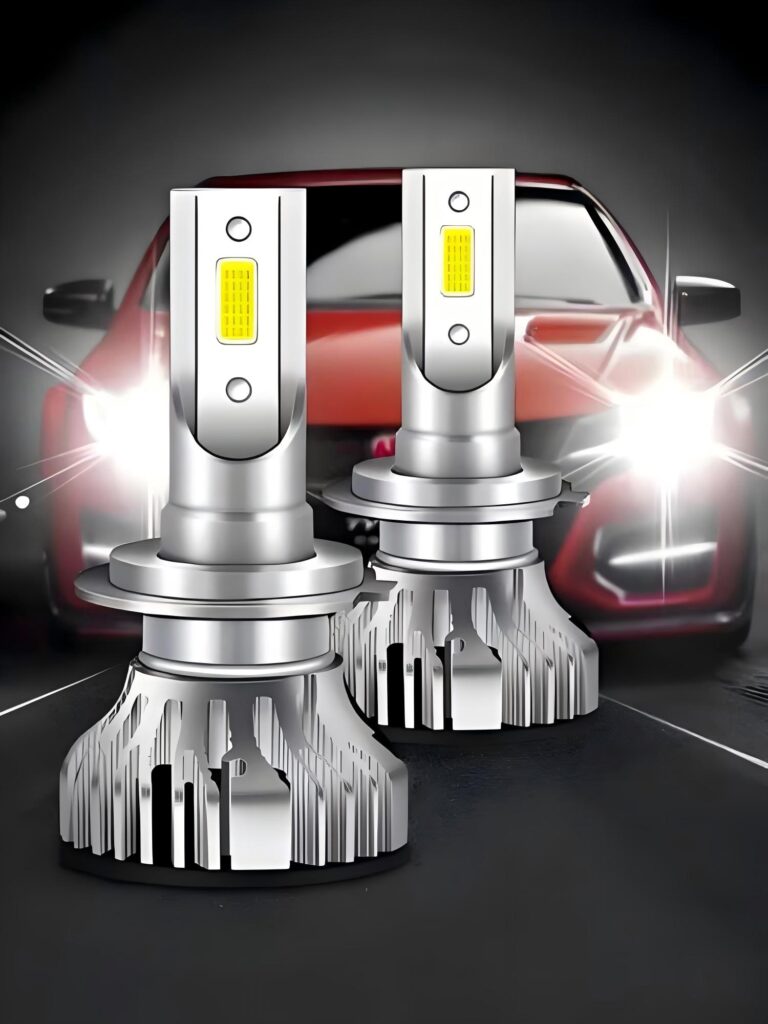

Applications: Headlights, dashboard components, sensors, interior trims, electronic modules.

Benefits: Vibration resistance, heat stability, chemical durability for harsh conditions.

Applications: Glassware, resin art, crystal ornaments, luxury decor.

Benefits: Invisible bonding, bubble-free finish, high visual clarity.

Applications: UV coatings, protective layers, 3D-printed parts, signage.

Benefits: Adjustable viscosity for varied coating methods, instant curing for faster delivery.

Applications: Structural glazing, glass panels, display cases, decorative installations.

Benefits: Long-lasting adhesion, transparent seals, weather resistance.

Applications: Transparent boxes, tamper-evident seals, luxury product enclosures.

Benefits: Strong hold, crystal-clear finish for high-end presentation.

Applications: Fiber splicing, LED packaging, sensor bonding.

Benefits: Low signal loss, high optical clarity, precise component alignment.

Applications: Solar panel sealing, battery module encapsulation, energy storage systems.

Benefits: Moisture resistance, UV stability, thermal cycle durability.

UV curing adhesive is a liquid glue that hardens when exposed to ultraviolet light. The light triggers a photochemical reaction, instantly converting the adhesive into a solid bond. ODAKE UV adhesives cure in seconds, delivering high-strength, crystal-clear, and durable bonds for glass, metal, plastic, and other substrates.

ODAKE UV glue offers:

Instant curing – seconds instead of hours

Transparent finish – ideal for glass and optics

High bonding strength – resistant to heat, moisture, and chemicals

Precision control – only cures when exposed to UV light, reducing waste

Compliance – ROHS, REACH, FDA, VOC-certified for global industries

Yes. ODAKE UV adhesive is engineered for multi-substrate bonding, including ABS, PVC, acrylic, stainless steel, aluminum, ceramics, and glass. For hard-to-bond materials, our dual-cure technology (UV + moisture) ensures complete curing, even in shadowed areas.

Once cured, ODAKE UV adhesive delivers high shear and tensile strength, making it ideal for structural bonding in automotive, electronics, and glass assembly. Bonds resist temperatures from -40°C to 150°C (special grades up to 200°C) and maintain integrity under vibration, moisture, and chemical exposure.

Clean the surface – remove dust, oil, or moisture.

Apply adhesive evenly to one surface.

Align parts accurately.

Expose to UV light (wavelength 365–405nm) until fully cured.

For shaded areas, use dual-cure UV adhesive for complete bonding.

Properly applied, ODAKE UV adhesives create bonds that last years without yellowing, cracking, or losing adhesion, even under harsh industrial conditions.

📧 邮箱:hexuxinwang@odakeglue.com

📞 电话:+86-769-81617120 | +86-13711910698

📍 地址:广东省东莞市虎门镇龙岩东路十二巷23号

*We respect your confidentiality and all information is protected.

ODAKE is a trademark of Hexun Xinwang Adhesive.

We will arrange for a specialist to contact you immediately.